Model NO.: LSG90/33 Screw No.: Single-screw Computerized: Computerized Customized: Customized Capacity: 180-1000kg/H PLC Controlling: Siemens Main Electricity Parts: ABB, Rkc, Ormorn, Schnider, Delix etc Pipe Application: Gas and Water Supply Exported Market: Global Trademark: Leader Machinery Specification: ISO, GB, CE HS Code: 8477209000 Product Type: Pe Pipe Automation: Automatic Certification: CE, SGS, ISO9001:2008 Condition: New Raw Material: PE80, PE100 Granules Diameter Range: 200-1200mm Quality Control: Customers Come to Our Factory to Check Delivery Time: 50days Guaranteed Time: 1 Year Transport Package: Wooden Case or Other Moistureproof Packages Origin: Qingdao China

Product Information

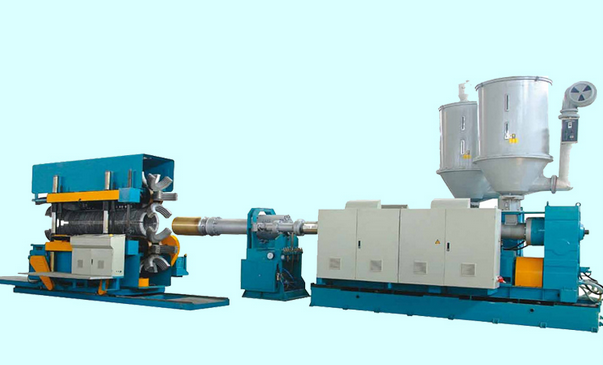

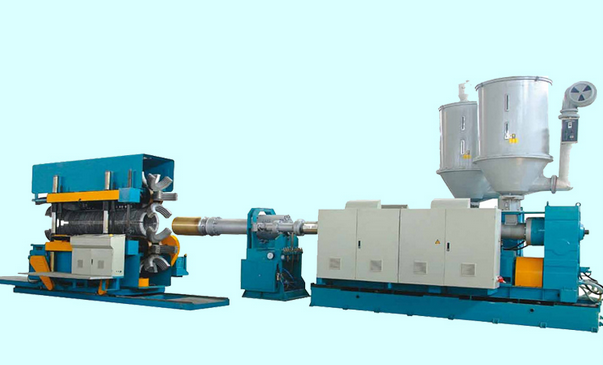

This

Pipe Extrusion line suits to produce the polyolefin pipe as HDPE,

Pp,PE etc in high production speed. It is of low power consumption, high output, high automation and reliable production.

Equipped the high efficiency

Single Screw Extruder designed by us according latest technology and our innovation.

Optimized spiral die ensure the melt distribution uniform to make the pipe wall uniform and guarantee the pipe pressure. Equipped copper Vacuum calibration sleeve with water lubrication ring, twin-chamber vacuum tank with spraying cooling and semicircular Nylon support, to ensure fast calibration, increase the production capacity and lower the operation. These designs are especially good for big diameter pipe production and high speed production.

All of vacuum tank and water cooling tank is made from stainless steel, dual water supply pipe line with filtration system, water level and temperature control system and optimized positioning of the bayonet-type spray nozzles.

The twin or multi caterpillar haul-off unit is equipped with high quality rubber block or rubber belt(for high speed production) accuracy driving and control system ensure the speed stable and running reliable.

Accurate non-scrap cutting machine (less than 160mm) and planetary cutting machine ensure the cutting section smooth and uniform.

DWC pipe is mainly used for water drainage system. It is a fully computer controlled line. It features high and stable output capacity, and highly automatic operation. For HDPE, you can choose high efficient single screw

Extruder. For

Pvc, you can choose conical twin-screw extruder or parallel twin- screw extruder. Forming system consists mould and corrugator.

Mould blocks can be easily changed and they have air or water cooling system. The belling process is on line. High precision cutting can be guaranteed by cutting machine. The production line can also be equipped with Siemens PLC system.

Technical Parameter

| Type | Pipe Diameter(mm) | Output(kg/h) | Speed(m/min) |

| SJSZ-500 | 200-500 | 600-700 | 3 |

| SJSZ-800 | 200-800 | 1100 | 3 |

| SJSZ-1200 | 800-1200 | 1200 | 1 |

Pre-sale service:

To provide information and market research,to provide consultation,to provide many kinds of conveniences and market service,etc.

The main purpose of pre-sales service is to help customers make the project planning and system requirements analysis. Make our products maximum to meet clients' requirements. Also play the greatest overall economic benefits of customers' investment.

After-sale service:

To install products and test products freely for customers.

To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

To direct technology aspect of relevant use according to customers' requirements

To provide technical training for clients' employees.

To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support:

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information of chemical material manufactories.

To provide technical training for clients' employees.

FAQ:

Delivery, payment and services

1.delivery time: 50 days after receiving the deposit

2.payment terms:30% for the prepayment by T/T and 70% for the downpayment by T/T before delivery or irrevocable L/C at sight can be available, too.

3.Packing details: wooden pallets and cases with stretching films

4.Guaranteed time: 18 months for the machenical parts and 12 months for the electrical parts.

5.Service: we will send 1-2 engineers to customers' factory to help them install, test the machine and also train their workers, but customers should bear the round tickets, accommodation, and salary etc.

Qingdao Leader Machinery Ltd.,Co

Address: South of Yangjialin,Beiguan,Jiaozhou,Qingdao,China.

Mobile: 0086-15908975657

Tel/Fax:0086-532-82278979

Zip Code:266300

Website: http://www.extruder-cn.com

Contact us if you need more details on

HDPE Pipe Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about

Plastic Pipe Extrusion Line、

HDPE Water Pipe Extrusion Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Pipe Extrusion Line > HDPE Solid Pipe Extrusion Line