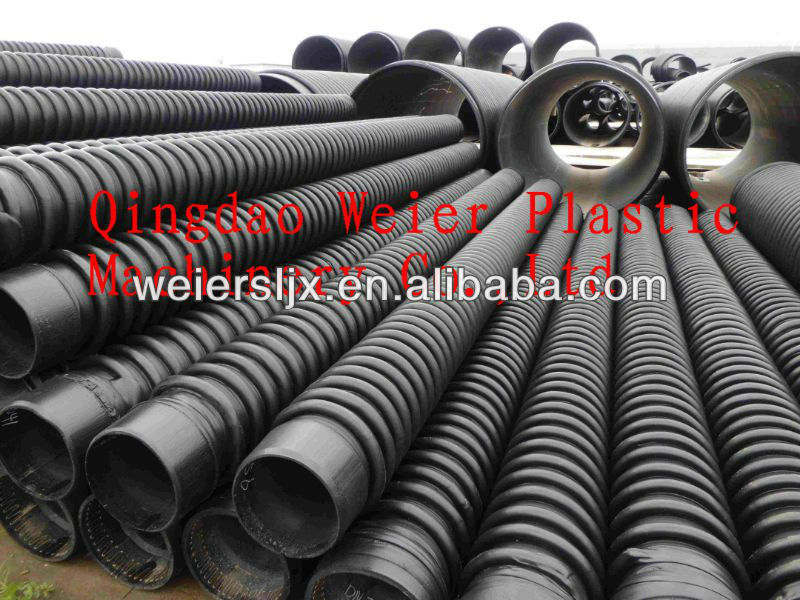

Specifications hdpe double wall corrugated

Pipe Machine 1.CE,ISO9001,SGS

2.make hdpe double wall corrugated pipe

3.various sizes for choice

Turn key project HDPE double wall corrugated pipe

Plastic Machine production line corrugated pipe machine contact: Tina Mobile: 0086-15908930795 skype: tina-supermachine plastic machine manufacturers since 1990s welcome all friends who are interested in our machine to be free to contact with me! About Us: Qingdao Weier Plastic Machinery Co., LTD is a professional manufacturer who is devoted to macromolecule science and plastic machinery and equipment, is the director member of WPC(Plastic &Wood Production Council of Chinese Plastic Community), now we are Plastic Engineering Technology Research Institute of Qingdao Science and Technology University Test and Industrialization center. We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer’s requirement and have a strong association with many macromolecule and chemical majors of many universities. At the same time we bring in and absorb advanced processing engineering of foreign plastic machines to realize chain service of technics and machines.

Products use: Conduit pipe Air delivery pipe Threading pipe Electrical wire jacket pipe High precision and good interchangeability for the shaping machine and die head Two ways to cool the moudle Tube end expansion is available online Unique digital controlling system is adopted to the whole production line Good automatcity,high output and stable running. Equipment List 1. Automatic loading machine 2 sets 2. Material drying system 2 sets 3. Single Screw

Extruder SJ65/30 2 sets 2. Die head and forming molds 3 sets 4. SBCJ-160 Forming-machine 1 set 5. STG-160 Planetary Cutting machine 1 set 6. Tilting table 1 set 7. Controlling system 1 set Detailed technical parameters 1.Automatic loading machine, 2 sets

Loading capacity | 300kg/h |

Loading distance | 4 m |

Storage hopper volume | 7.5 L |

Feeding pipe diameter | 38mm |

2. Material drying system, 2 sets

Material volume | 50KG |

Electrical heating for drying | 6.5kw |

Fan power | 180W |

3.SINGLE SCREW

Plastic Extruder SJ65X30 2 sets

Barrel screw | Hardness of screw HV>740 |

Material 38CrMoAlA nitriding treatment | Hardness of barrel HV>940 |

Depth of barrel nitriding | 0.4--0.7mm |

Depth of screw nitriding | 0.3-0.6mm |

Diameter of screw | 65mm |

L:D | 30:1 |

Heating& cooling |

Barrel heating zone: | 4 zones, 16KW |

Barrel cooling zone | 4 zones*0.18kw |

Driving |

AC motor rotating speed | 1480r.p.m |

Speed frequency converter | 37kw |

Reduction gearbox | Gear transmission |

Gear material | High strength alloy steel, under carburization and quenching treatment |

4.DIE HEAD and moulds 3 sets 100mm,140mm,160mm 5.FORMING-MACHINE SBCJ-160 ( with automatic lubrication system) 1 set 6.Planetary Cutting machine STG-160 1 set Cutting range 100-160 Compressed air 0.4~0.8Mpa Outer dimension 3500*2400*3100mm 7.Storage table SDF-6000 1 set length: 6000m Material of stacker stainless steel, polishing cylinder tilting 8 Controlling system 1set Temperature control PID system Contactor Delixi Frequency converter SIEMENS Button & indicator TE from France

after-sale service and technology: (1)the supplier provide service manual and maintenance instruction of main electric appliance,limb,usage manual of equipment.We also supply water,electricity,gas of equipment and installation drawing. (2)the supplier is responsible for installation,debugging and training, but the air tickets, insurance,eating,housing and every day 50 USD for each engineer will be borned by the buyers. we will realize guarantee of repair; replacement and refund of substandard products within one year after the machine leaves factory. And half a year for electric parts . Fittings of the machine will be supplied at preferential price after one year . “Excellent Quality and Reasonable Price” is our company’s quality policy; “Honest Service and Win-win Cooperation” is our company’s core concept. we offer turn key project, with lifelong after sale service! we have ready machines in factory for your test and visit! sincerely welcome all friends to visit our factory!

Contact us if you need more details on Corrugated Pipe Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about

Pvc Corrugated Pipe Machine、Hdpe

Pipe Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : PP,PE,PPR,PVC Pipe Production Line > Other Pipe Production Line

Products use: Conduit pipe Air delivery pipe Threading pipe Electrical wire jacket pipe High precision and good interchangeability for the shaping machine and die head Two ways to cool the moudle Tube end expansion is available online Unique digital controlling system is adopted to the whole production line Good automatcity,high output and stable running. Equipment List 1. Automatic loading machine 2 sets 2. Material drying system 2 sets 3. Single Screw Extruder SJ65/30 2 sets 2. Die head and forming molds 3 sets 4. SBCJ-160 Forming-machine 1 set 5. STG-160 Planetary Cutting machine 1 set 6. Tilting table 1 set 7. Controlling system 1 set Detailed technical parameters 1.Automatic loading machine, 2 sets

Products use: Conduit pipe Air delivery pipe Threading pipe Electrical wire jacket pipe High precision and good interchangeability for the shaping machine and die head Two ways to cool the moudle Tube end expansion is available online Unique digital controlling system is adopted to the whole production line Good automatcity,high output and stable running. Equipment List 1. Automatic loading machine 2 sets 2. Material drying system 2 sets 3. Single Screw Extruder SJ65/30 2 sets 2. Die head and forming molds 3 sets 4. SBCJ-160 Forming-machine 1 set 5. STG-160 Planetary Cutting machine 1 set 6. Tilting table 1 set 7. Controlling system 1 set Detailed technical parameters 1.Automatic loading machine, 2 sets