Model NO.: LSG65/33, 75/33, 90/33 Screw No.: Single-screw Computerized: Computerized Customized: Customized Main Motor Power: 30-55kw Max Capacity(Kg/H): 100-250kg/H Main Electrical Components: Rkc,ABB,Simens, Schneider etc Guaranteed Time: 18 Months Dimension(L*W*H): 22m*2.5m*2m Trademark: Leader Machinery Specification: CE ISO9001-2008, GOST, SGS HS Code: 8477209000 Product Type: PPR Pipe Automation: Automatic Certification: CE, SGS, ISO9001:2008 Condition: New Voltage: 3 Phase,380V,50Hz or Customized Pipe Diameter Range: 16-110mm Engineers: Available Colour: White or Customized Weight: 5.5t Transport Package: Wooden Case or Other Moistureproof Packages Origin: Qingdao, Shandong, China Factory sell PPR plastic

Pipe Making machine Part one Introduction Using a special screw design and enhanced plasticization effect of

Pp-R to ensure high-quality high-speed extrusion, high shear stress and low temperature to ensure that raw materials of high-performance plastics extrusion, the measurement on the feeder with the drying system to ensure that PP-R extrusion uniform.

Part two Technical data

| Model/data | Pipe diameter | Extruder model | Co-extruder | Line speed | Max capacity | Installed power | Dimension | weight |

| LPG65/30 | 20-63mm | LSJ65/30 | SJ-25/25 | 1-10m/min | 120kg/h | 55kw | 32*3.0*2.2m | 9.5t |

| LPG90/30 | 75-160mm | LSJ90/30 | SJ-30/25 | 0.2-4.5m/min | 260kg/h | 120kw | 36*3.1*2.2m | 12.5t |

| LPG55/55/55 | 20-63mm | LSJ55/30 | SJ-25/25 | 1-8m/min | 150-180kg/h | 120kw | 32*5.1*2.2m | 15.5t |

Part Three Specifications

Advantages

1.High output capacity

2.Low energy consumption

3.High precise

4.Long using

PP-R pipe extrusion line main features:

1. Well made high quality single screw extruder with exclusive helical gear reducer and high effiency converter motor, make high speed extrusion;

2. Special screw structure, high shear stress low temperature, ensure high quality plasticization;

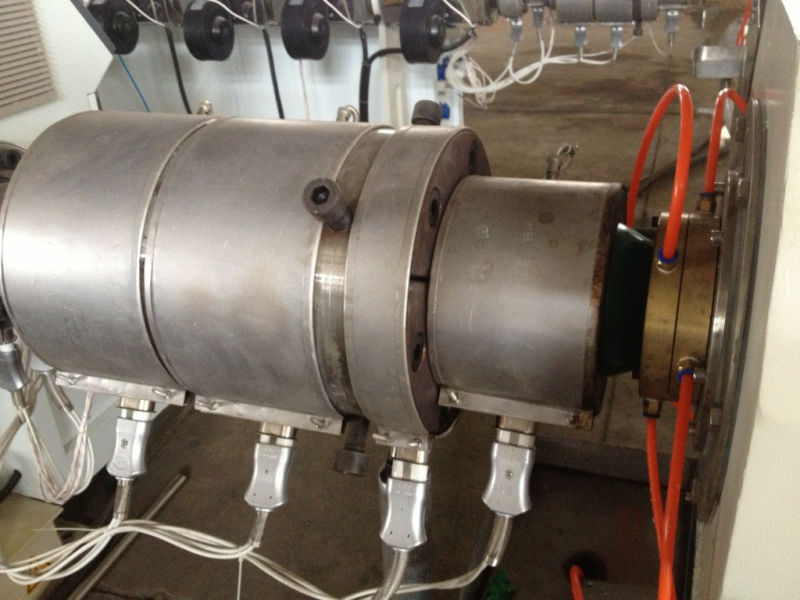

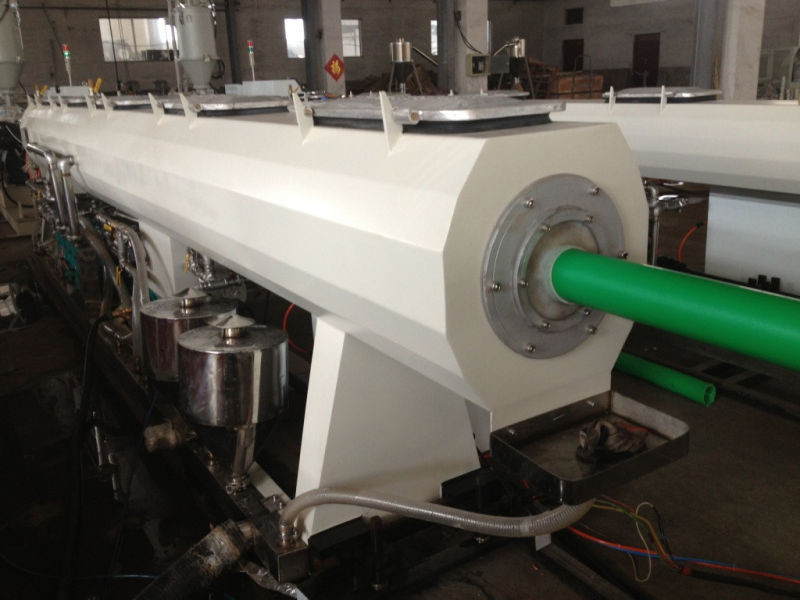

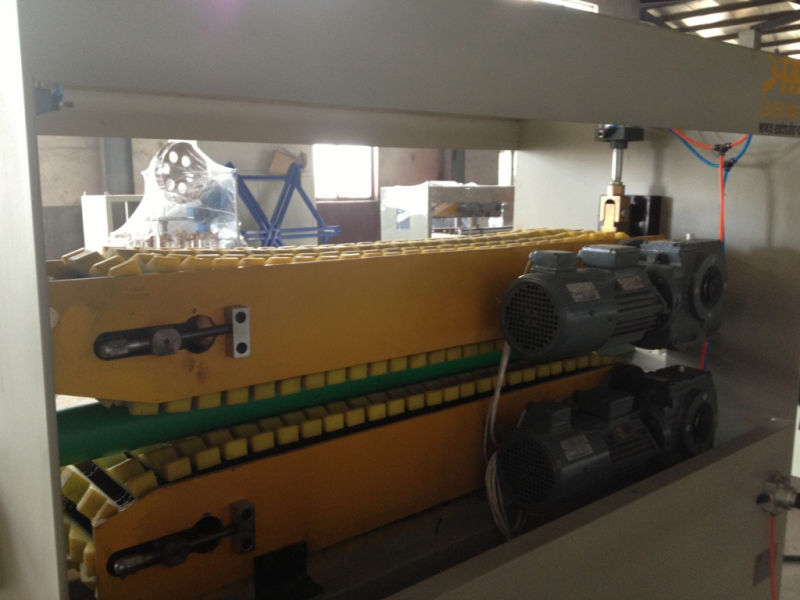

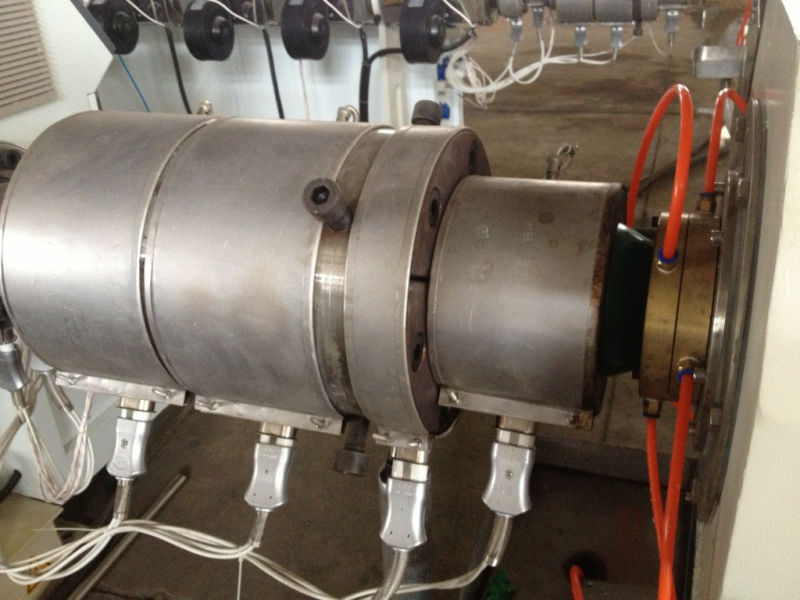

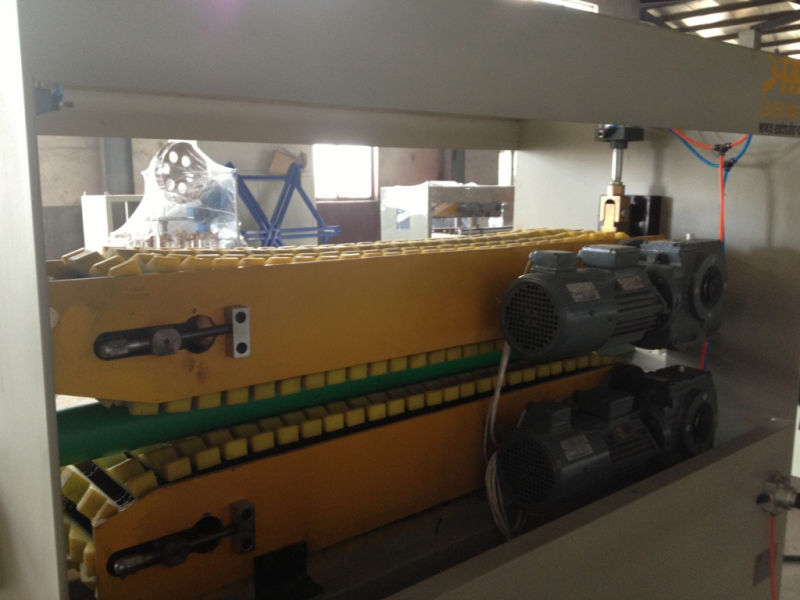

3. High precise spiral runner extrusion die head, tin bronze groove type vacuum calibrating sleeve, stable vacuum degree calibrating tank, high effective water spray cooling system, uniform speek and high traction force NBR caterpillar haul-off machine help making perfect PP-R pipes;

4. Whole line with high degree of automation, easy to operate;

5. High quality steel materials, strict producing proces make high quality line;

6 New advanced energy saving technology, lowered energy consumption;

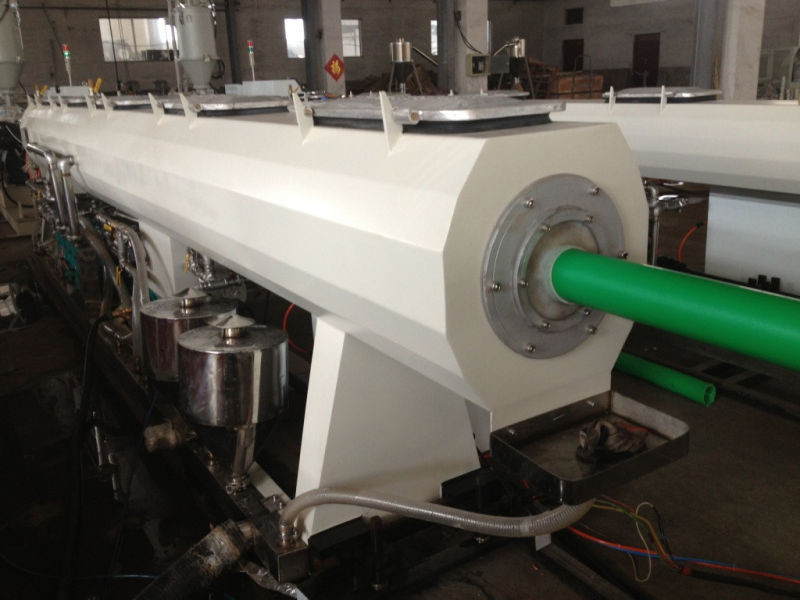

7. Whole line adopt newes desigh concept, using well known brand electrical components, enhanced line stability. Part Four Testing pictures

Contact us if you need more details on PPR

Pipe Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PPR Pipe Making Machine、PPR Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Pipe Extrusion Line > PP/ PE/ PPR/PERT Pipe Extrusion Line

Contact us if you need more details on PPR Pipe Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PPR Pipe Making Machine、PPR Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on PPR Pipe Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PPR Pipe Making Machine、PPR Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.