Model NO.: SJSZ-65/132(YF-240) Screw: Double-Screw Computerized: Computerized Customized: Customized

Extruder Model: Conical

Twin Screw Extruder 65/132 Die Head Type: Double Extrusion Type Main Electrical Parts: ABB, Omoron, Delix, Schnider, Rkc etc Machine Diemension: 24m*2.2m*1.8m Trademark: Leader Machinery Origin: Qingdao of China Product Type:

Pvc Profile Automation: Automatic Certification: CE, ISO9001:2008, SGS Name: PVC Edge Trim/Trimming

Extrusion Line Applications: Edge Trimming in Construction Vacuum Calibrating Table: 6000mm Guaranteed Time: 12 Months Transportation: 2 Sets of 40gp Containers Specification: SJSZ65/132 HS Code: 84772090 pvc edge trimming/trim extrusion line edge trim making machine

PART 1 INTRODUCTION:

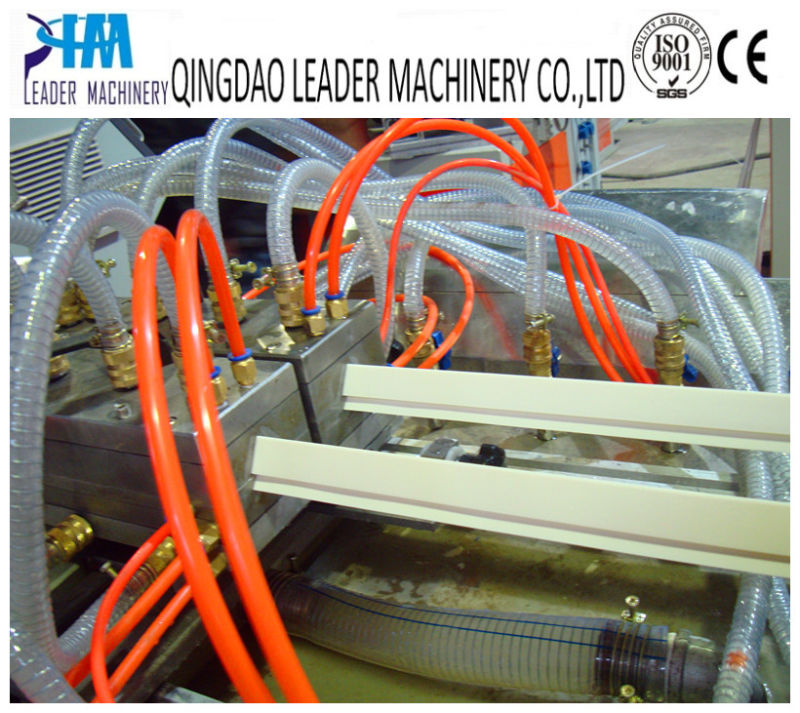

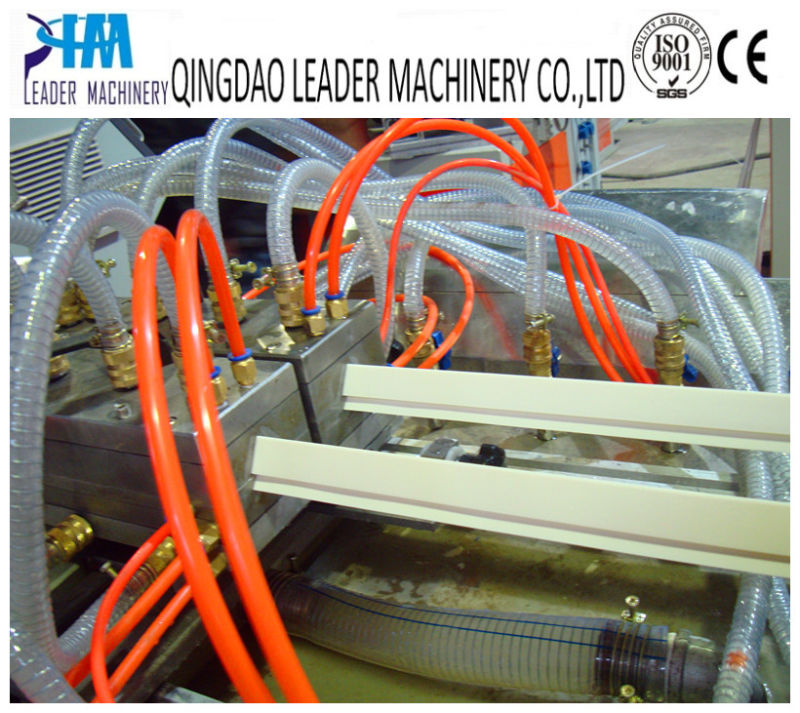

The machine is mainly designed to produce PVC,edge trim profiles, by changing die head part, it can also produce other kinds of different profiles.This unit consist of conical twin screw extruder, die head, vacuum calibrating table, haul off and cutting machine, stacker etc.

This line has the advantages of good plasticization, high capacity, low energy consumption etc. The motor of main extruder and haul off machine adopt imported AC frequency inverter. Thermo-controllers adopt RKC brand; contactors adopt Schneider brand, France. Both vacuum pumps and water pumps adopt good brands, easy to maintenance.

PART 2 PERFORMANCE AND ADVANTAGES

1. Extruder: adopting specially screw designs according to different materials make the high polymer micro-foam uniform plasticization, high extrusion. Imported famous brands AC inverter makes the rotation speed stable to ensure the main extruder and accessory machines move synchronously.

2. Did head and Vacuum calibrating table:

adopts powerful turbo cooling system, easy to achieve satisfactory cooling effect. According to different moulds and different customer requirements, the vacuum calibrating table can be optional as 4m, 6m.

3. Haul off machine: adopts special lifting technology, and has the features of stable running, reliable working, powerful hauling etc,

4. Cutting machine: the moving speed of the cutting unit is synchronized with hauling speed. Through prsetting,the cutting uit is capable for automatic cutting with fixed length. Dust recycling device is also equipped.

PART 3 DELIVERY,PAYMENT AND SERVICES

1. delivery time: 50 days after receiving the deposit

2. payment terms:30% for the prepayment by T/T and 70% for the downpayment by T/T before delivery or irrevocable L/C at sight can be available, too.

3. Packing details: wooden pallets and cases with stretching films, it will need 2 sets of 40GP continers

4. Guaranteed time: 18 months for the machenical parts and 12 months for the electrical parts.

5. Service: we will send 1-2 engineers to customers' factory to help them install, test the machine and also train their workers, but customers should bear the round tickets, accommodation, and salary etc.

Contact us if you need more details on Pvc Edge Trimming Profile Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pvc Edge Trim Profile Extrusion Line、Pvc Edge Trimming Profile Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Profile Extrusion Line > PVC/PP/PC Small Profile Extrusion Line